A refrigeration plant produces not only cooling but also a lot of energy that is usually wasted to the environmental air. The warm side temperature level is too low to drive an ORC unit, but energy can be used in other ways. Either directly through heat exchangers or it can serve as a heat source for heat pumps.

Below is a typical example of the huge potential for saving that can be achieved in an Ice Arena with the same or better ice quality for skaters and players. And with no sacrifice in comfort for spectators, personnel and hockey players.

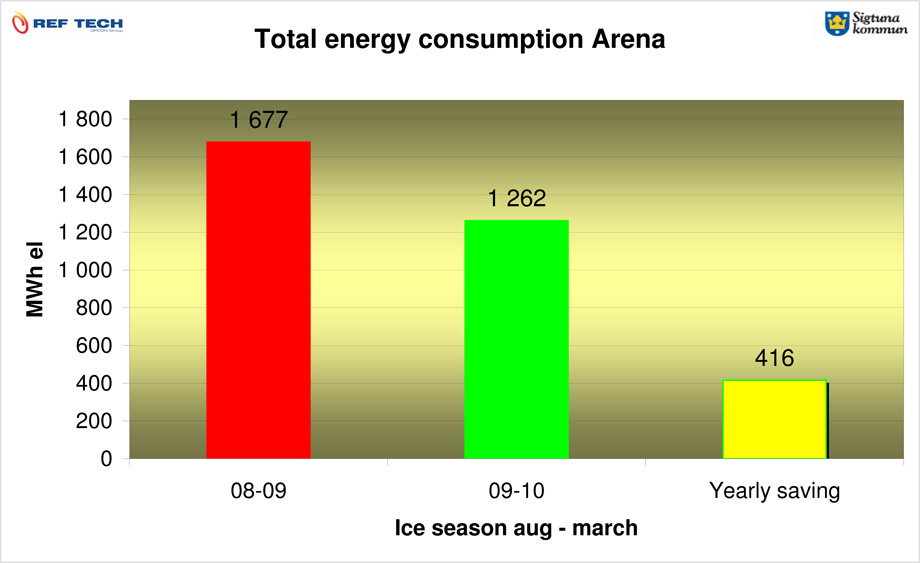

Pic 1. Seasonal summary

Seasonal consumption before improvement in RED

Seasonal consumption after improvement in GREEN

Seasonal saving in YELLOW

A yearly saving of operational costs of 0.5 MSEK or roughly 50 000 EUR is within reach, this is true for a vast majority of Ice Arenas.

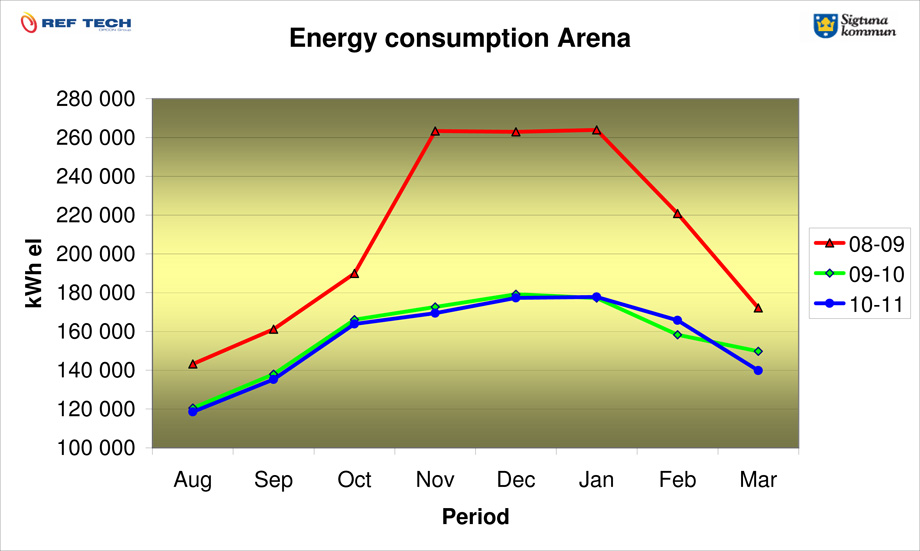

Pic 2. Consumption of energy on monthly basis

The RED line represents consumption of energy before improvement.

The GREEN line the consumption first year after improvement.

The BLUE line verifies that the good conditions prevail.

Other example:

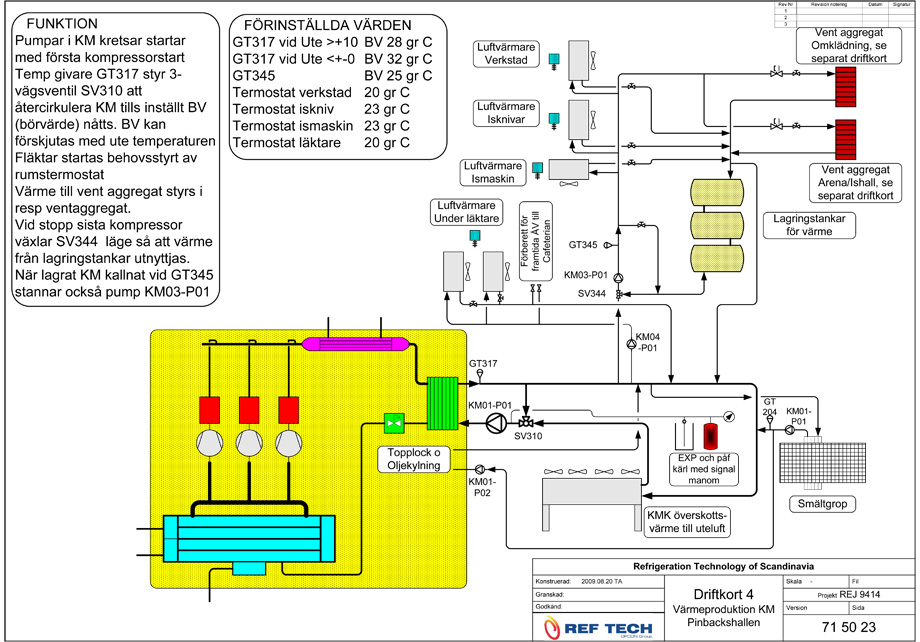

Pinbackshallen

An existing indoor ice rink had all of its needs covered by electricity, both cooling and heating.

The plant was modified with hot gas heat exchangers on approx 80ºC level to deliver hot water to the warm water accumulators for showers and for make-up water for the ice resurfaceing machine.

The condenser heat at approx 35 ºC level was used directly to heat premises such as work shop, garage for ice machine, for storage rooms and through heat exchangers in the ventilation of dressing rooms and the arena itself.

Energy savings is in the order of 25 to 30% compared to the situation before modification.

Pay-back time is less than 4 years and with increasing energy prices to be expected in the future this is indeed a sound investment.

Enebyberg IP

They have an indoor ice rink with an anti- freeze piping system installed under the ice bed.

This was never made operative and after 10 years of operation the bed started to heave.

We installed a hot gas heat exchanger to provide warm water that was primarily used to heat all tap warm water via two accumulators. In the return pipe to the hot gas heat exchanger we also installed a small plate heat exchanger to make +15 ºC warm glycol. This glycol is circulated in the ground under the rink to prevent from freezing the ground water.

Main objective was to prolong the life time of ice rink and not to save energy. However, by combining these two aims a considerable reduction of electrical energy has been achieved.

There are several other similar installations made but all are adapted to the actual need in each individual case.